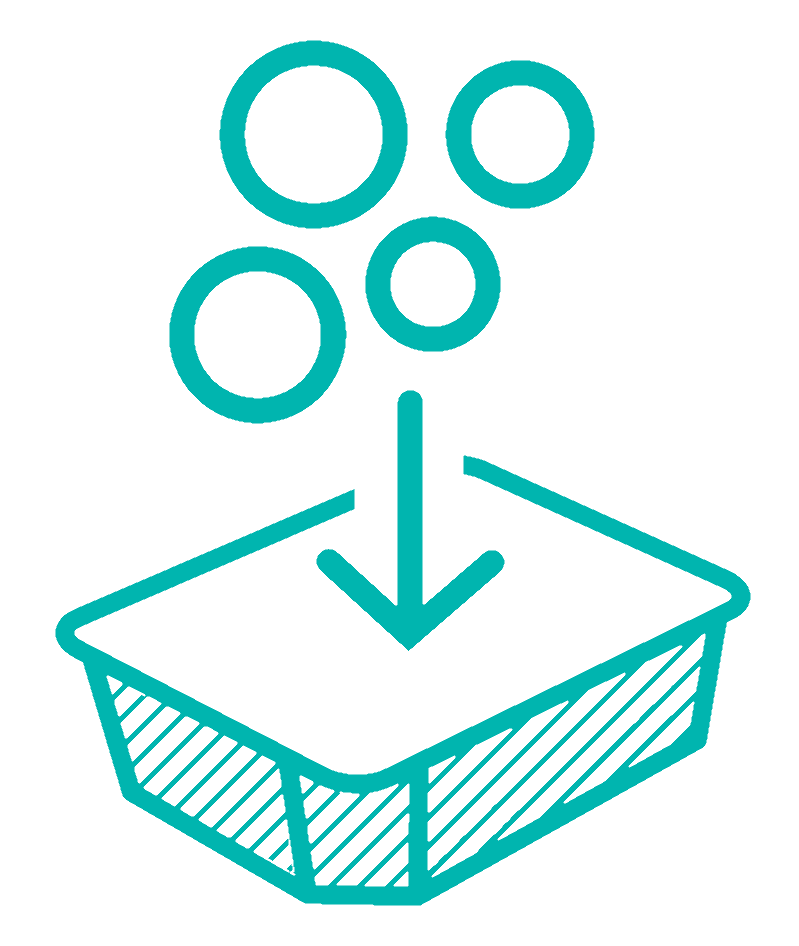

Jospak® carton tray can be coated with only a thin plastic film. The tray decreases the need to use plastic by 85% and significantly reduces CO2 emissions compared to similar packaging solutions made fully out of plastic.

Jospak® trays are made from renewable wood fiber originating from sustainably managed forests. A renewable raw material like trees grow back through natural processes. Our supply chain is FSC® CoC certified.

Brand and product information can be printed directly onto the tray, thus also helping with the challenge of overpacking.

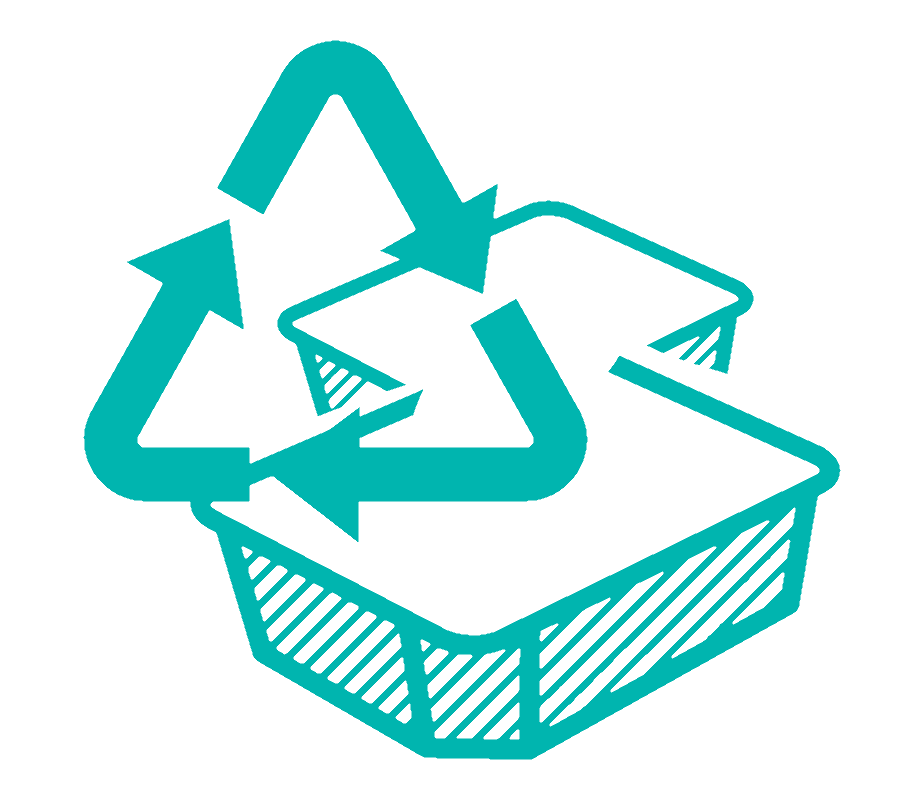

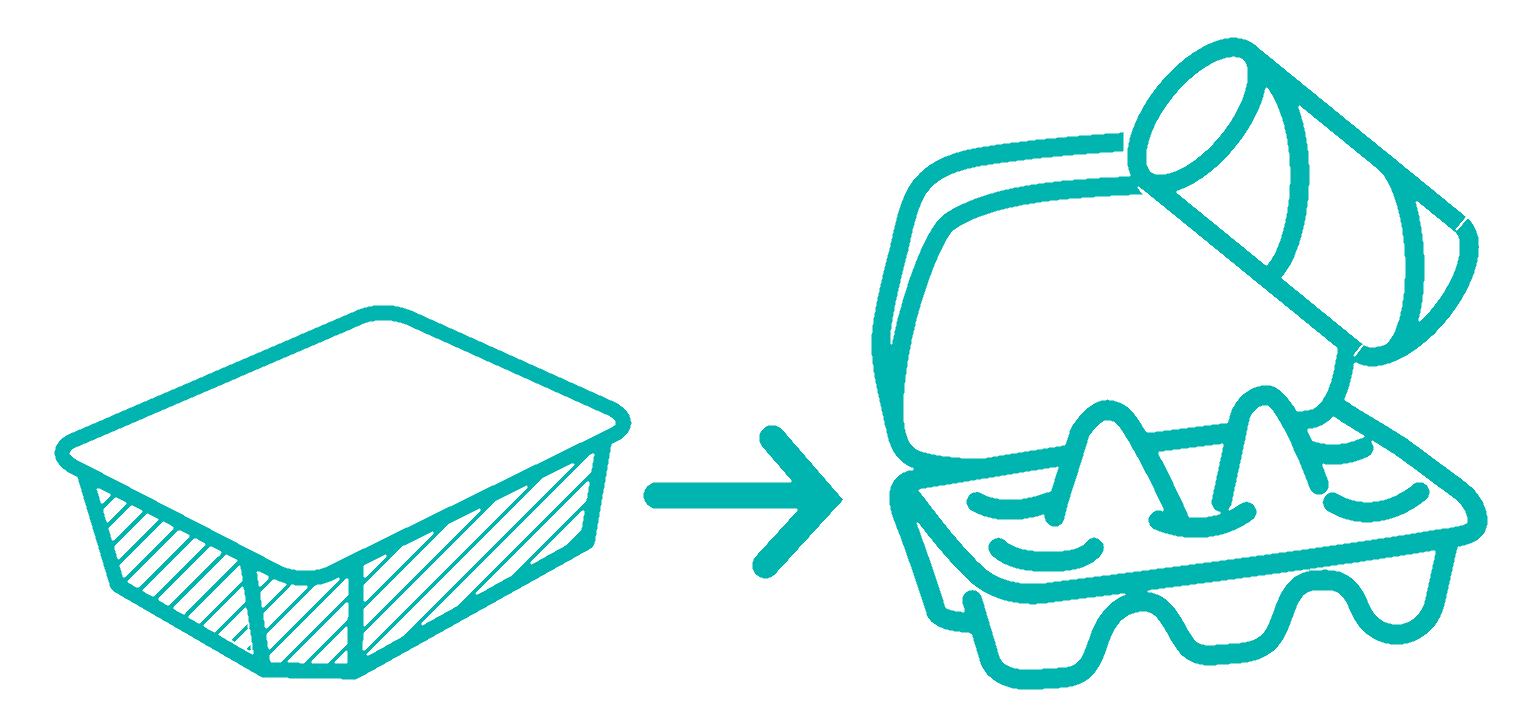

Recycling of the Jospak carton package is easy, as the consumer can separate the plastic film and recycle both materials in separate waste management systems.

Jospak® carton tray can be coated with only a thin plastic film. The tray decreases the need to use plastic by 85 % and significantly reduces CO2 emissions compared to similar packaging solutions made fully out of plastic.

Jospak® trays are made from renewable wood fiber originating from sustainably managed forests. Our supply chain is FSC® CoC (FSC® C151779) certified. The Forest Stewardship Council® (FSC®) sets the standard for responsible forestry worldwide.

Brand and product information can be printed directly onto the tray, thus also helping with the challenge of overpacking.

Recycling of the Jospak carton package is easy, as the consumer can separate the plastic film and recycle both materials in separate waste management systems.

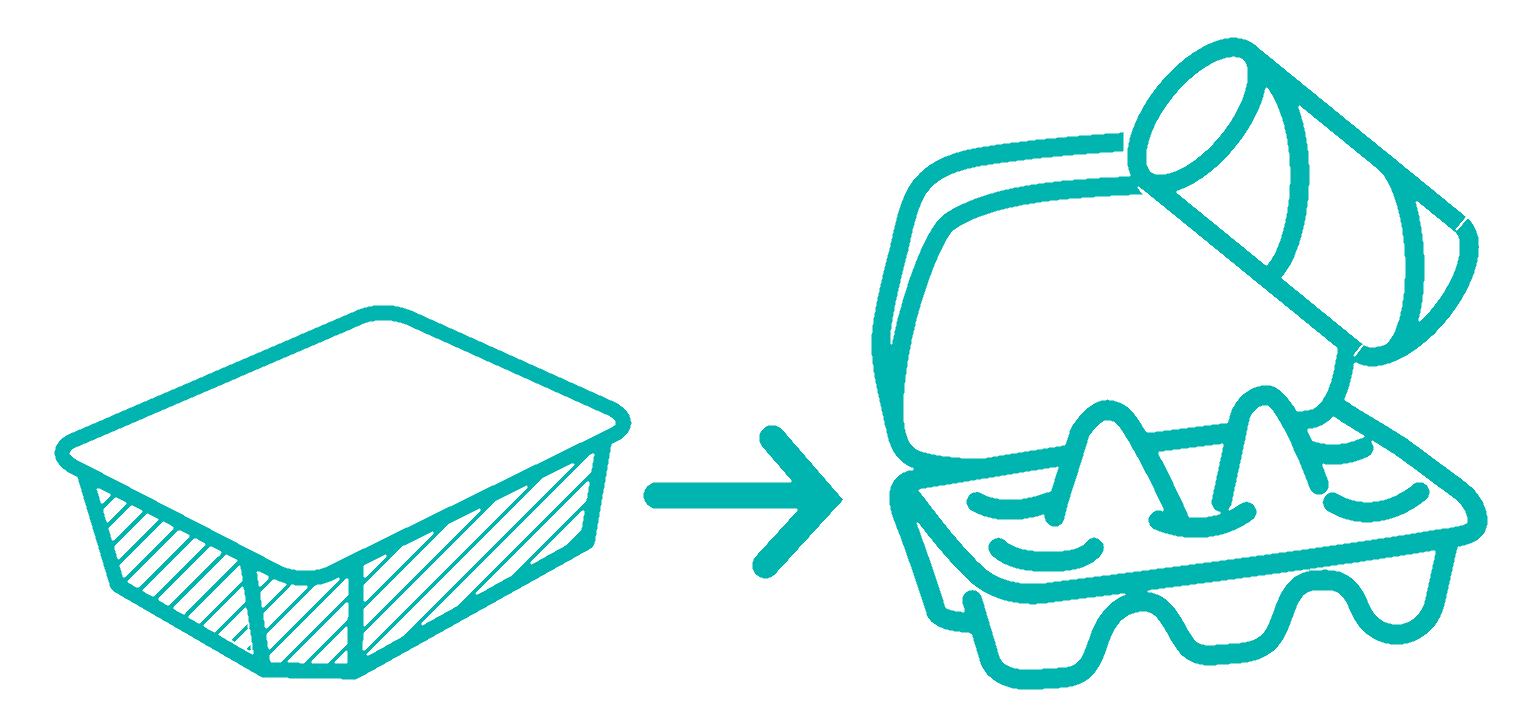

Fiber material is produced into carton and printed according to customer's design

Printed carton is delivered to Jospak® factory

Jospak® carton trays are produced in the Jospak® factory

The trays are delivered to the customer

Fiber material comes from sustainably managed forests

The trays are packed with different food products

The carton material can be recycled up to 4-7 times into new products

The consumer buys, uses and recycles the tray

The products are sold in stores

Fiber material comes from sustainably managed forests

Fiber material is produced into carton and printed according to customer's design

Printed carton is delivered to Jospak® factory

Jospak® carton trays are produced in the Jospak® factory

The trays are delivered to the customer

The trays are packed with different food products

The consumer buys, uses and recycles the tray

The products are sold in stores

The carton material can be recycled up to 4-7 times into new products

In our sustainability work, we are particularly committed to three different areas: caring about the environment, people and safety, we are a responsible partner for a more sustainable packaging and food industry.

We want to be responsible in our daily work. We have reviewed and developed our factory's energy solutions, transport emissions and our own waste management together with our partners.

We are committed to ensure the health and safety of our employees. The basic rights of employees in the supply chain are also protected in the FSC® CoC (FSC® C151779) certificate admitted to us.

We start from the fact that every person operating under our roof has a safe environment to work and visit. We do concrete things for the safety of our work environment.

Jospak is engaged with continuous development, product safety and quality. Our work has been honored by the British Retail Consortium. We also use carton made from responsible sources only. Therefore, all Jospak® trays are ensured by FSC® Certification. We are also certified with The Strongest in Finland AA-certificate which is granted for companies with high credit rating. It is a sign of our creditworthiness, good payment behavior and reliability. The rating is granted by Suomen Asiakastieto Oy.

Kuulalaakerintie 6

30100 FORSSA, FINLAND

+358 20 730 7860